Tornalama

Frezeleme

Delik Delme

Hassas Takım Tutucular

Ölçü Aletleri

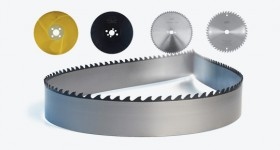

Testereler